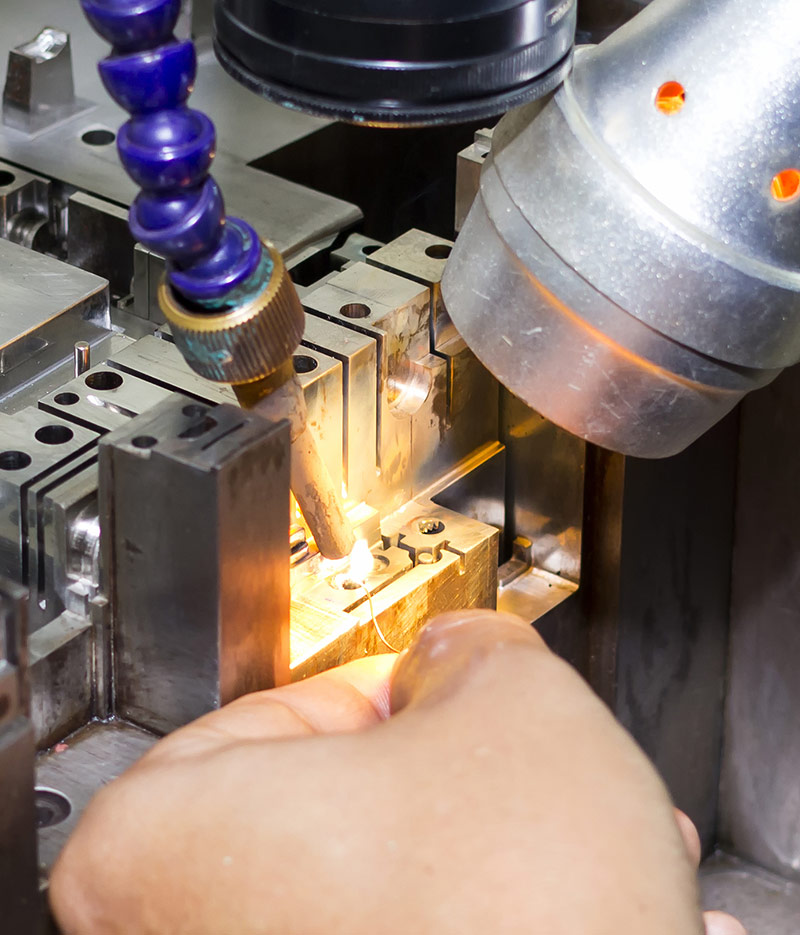

SWS-Trimac provides Laser Welding services for a wide range of industries and offers many options in both CO2 and solid-state fiber Laser Welding technologies. These processes are capable of welding thicknesses ranging from foil to 3/8” of an inch in Carbon Steels, Stainless Steels, Copper, and Aluminum, just to name a few.

Laser Welding processes generate light energy that can be absorbed into materials and converted to heat energy. By employing a light beam, we can transmit this energy from its source to the work piece, using an array of delivery optics, which can focus and direct the energy to a very small beam spot. The typical spot size of the laser is approximately .012” in diameter. The focal point can be adjusted above or below focus; this variable will affect both weld penetration and the width of the weld signatures, which is very important depending upon joint design and application. The speed of welding is proportional to the amount of power supplied but also depends on the material type and thickness of the work pieces.

Laser Welding may be used in a continuous or pulsed mode, depending upon the type of Laser Welding technology.

Laser Hotwire, the laser beam heats the base metal. The pre-heated wire is fed in, and brazed or welded with the base metal. The result is a fusion zone with added ductility for crack sensitive applications or added volume for those applications with excessive joint gaps or chamfers. This can be reliably done at high welding speeds, great weld quality that is nearly spatter-free which offers very fast cycle times and less rework potential.

In this process, the laser beam is directed by moving mirrors. The welding head guides the laser beam over the workpiece. A processing field emerges which enables highly dynamic and precise welding. Due to the very fast translation movements of the mirrors, non-productive times are reduced increasing the available production time. SWS-Trimac uses these PFO scanners in conjunction with CNC controlled multi axis welding cells.

We strive to be your path of least resistance. Often times, solutions do not always come easy. But, our perseverance in investigating alternative joint designs, fixturing, manufacturing techniques and materials, pays off!

Contact us and see how we can help.

© 2020 All rights reserved | SWS Trimac INC.