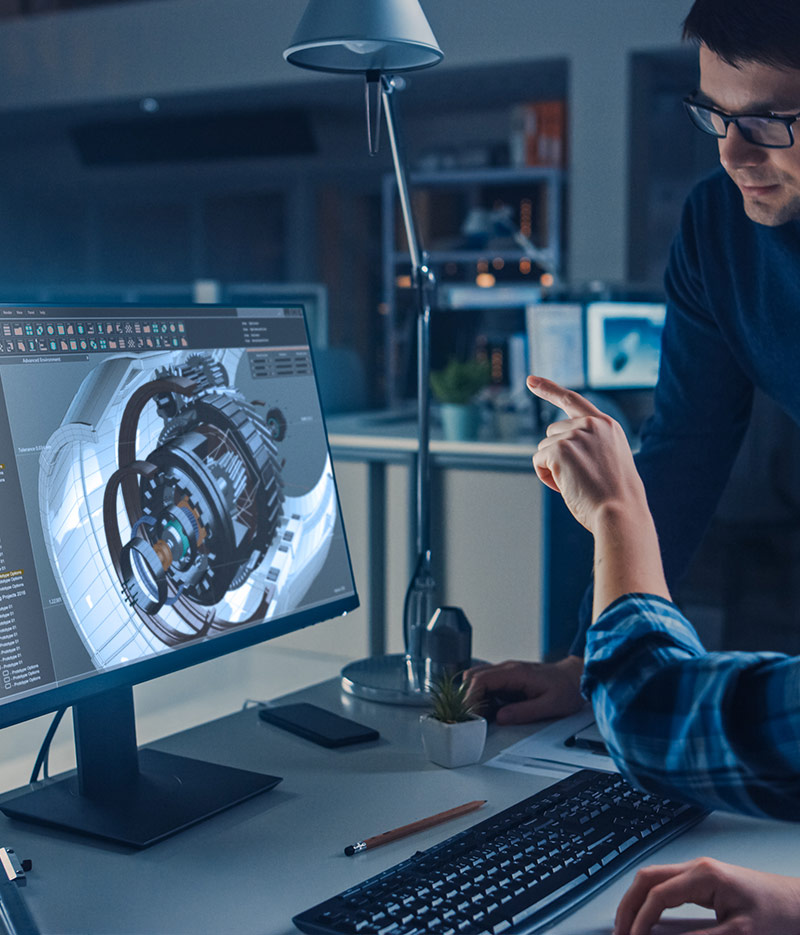

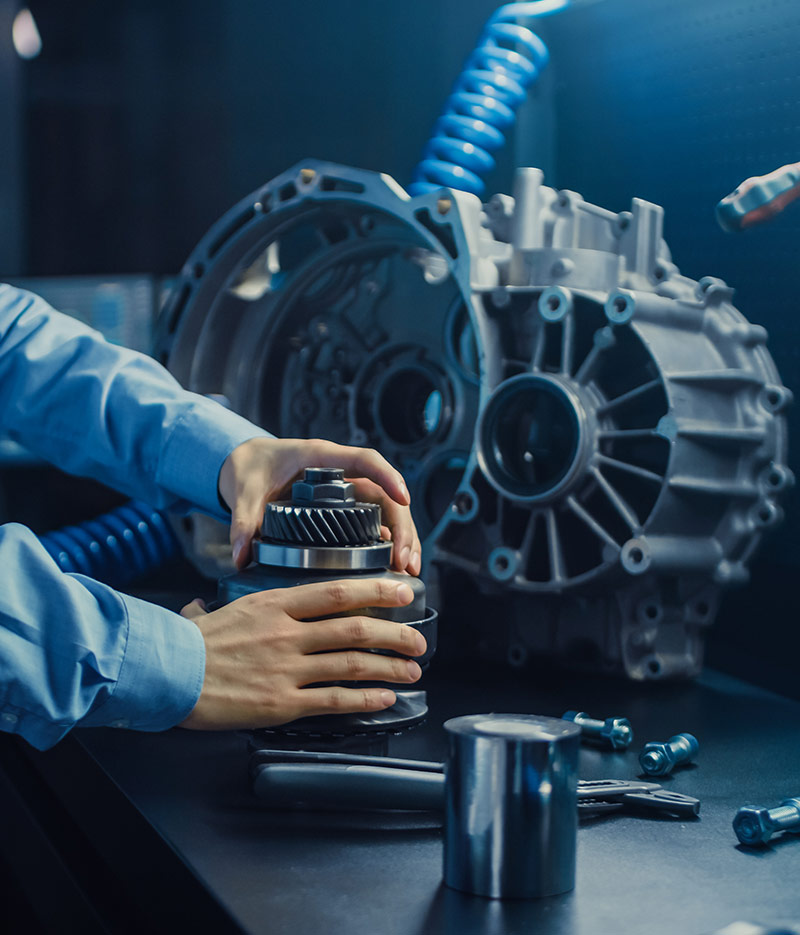

SWS-Trimac Engineering Department strives to assist customers in achieving satisfactory results with each project, using advanced manufacturing practices such as Electron Beam Welding and Laser Welding. Typical requests include aiding clients in the design of weld joints that will comply with customer strength and hardness requirements, material selection, and machining techniques both pre-& post-weld, maintaining some of the industries tightest tolerances.

SWS-Trimac has over 50 years of experience in Engineering support, of various products serving many industries, including Aerospace, Medical, Automotive, Defense, Commercial and Chemical.

In a job shop environment, customer expectations vastly differ from those of others, dependent upon industry. Lessons learned and over fifty years of experience in contract services makes SWS-Trimac a valuable vendor to our customers.

SWS-Trimac has manufactured a countless number of tools to manipulate customer product under stationary weld beams since 1967.

Many new projects require special tooling or work holding specific to customer applications.

These special tools are often adapted to an existing SWS-Trimac universal fixture which saves our customers valuable lead-time with smaller, upfront tooling investments, and in some cases at zero expense.

For those customers whom want dedicated fixtures, SWS-Trimac can manufacture from concept to production.

Native Solid Edge:

Assembly – (.asm)

Draft – (.dft)

Part – (.par)

Sheet Metal – (.psm)

Weldment – (.pwd)

Preferred Solid Models:

Parasolid – (.x_b & .x_t)

IGES – (.iges & .igs)

STEP – (.step & .stp)

Preferred 2d Cad Data:

Adobe Acrobat Reader – (.pdf)

AutoCAD – (.dwg & .dxf)

We strive to be your path of least resistance. Often times, solutions do not always come easy. But, our perseverance in investigating alternative joint designs, fixturing, manufacturing techniques and materials, pays off!

Contact us and see how we can help.

© 2020 All rights reserved | SWS Trimac INC.