SWS-Trimac specializes in Electron Beam Welding & Laser Welding for many of the major Medical Device / Instrument manufacturers to which we have been providing prototype & production Medical welding and machining services for more than 50 years. Our work has ranged from one of kind implants to thousands of tools & instruments, to millions of disposable tools being used daily. It is very likely that one of our welds is currently in a surgical procedure this very moment. Our QMS operates within ISO 13485:2016 for prototype, pre-production and production stages of manufacturing.

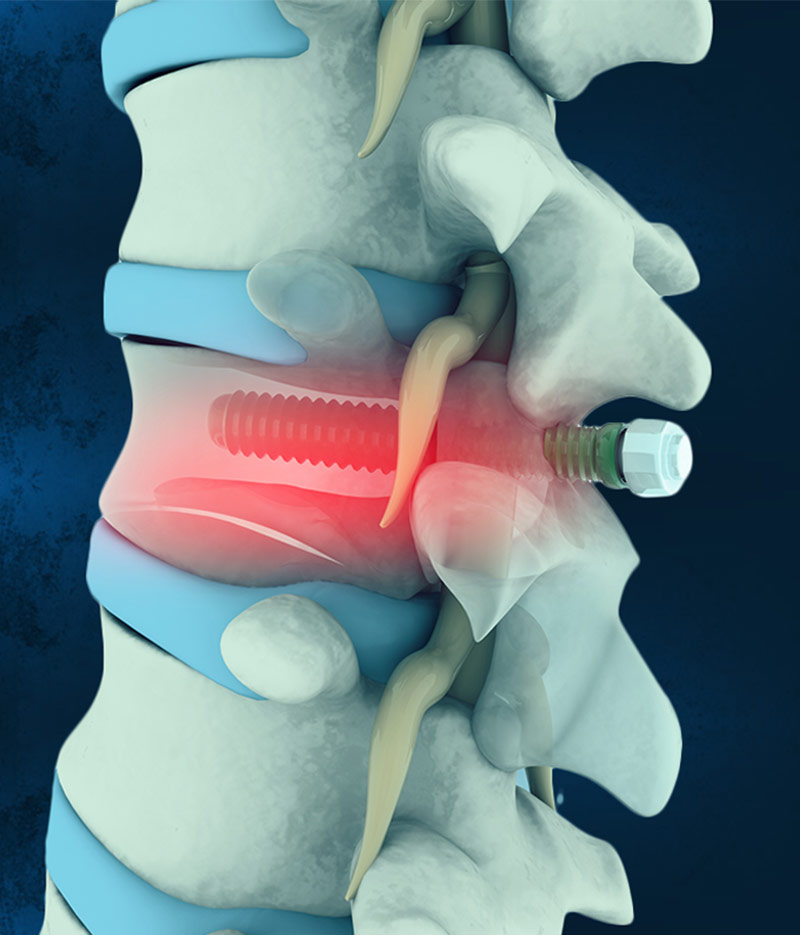

Electron Beam and Laser welding has been an obvious choice for the fusion welding of medical implants, instruments & hardware that require minimal distortion. Welds range from fine micro welding to deep cross sections exceeding an inch in depth. SWS-Trimac can add filler material for those challenging or difficult weld applications.

Electron Beam Welding offers a pure welding environment within a vacuum chamber utilizing existing base metals to create a weld without the use of filler material. While Laser Welding offers very fast cycles although requires a shield gas to protect the weld area from atmospheric gases during the weld process.

Alloys typically being Electron Beam or Laser Welded are 300 and 400 series Stainless Steels, Precipitation Hardening (PH) Stainless Steels, Aluminum, Titanium, Cobalt and even man-made tantalum porous metallic structures just to mention a few.

Many applications are finished to some of the highest of visual aesthetic requirements often completely concealing the welds visually. Typical customer annual volumes will range from 1 to 500,000 parts per year with an array of requested services.

SWS-Trimac aids in the manufacture of various instrumentation for spine, shoulder, hip, knee and dental devices, and implants just to name a few. Many very complicated with tight tolerances, precision assemblies requiring welding, machining or both. SWS-Trimac can perform your small prototype lot quantities or fulfill your production volume needs.

SWS-Trimac also offers full service machining, including Wire EDM, EDM Drill, CNC multi-axis Milling, Lathe Turning, Swiss Machining and Surface Grinding. In addition to these machining capabilities SWS-Trimac also offers surface finishing, blasting, Citric Passivation, Laser Marking, and packaging options.

Quality systems comply with ISO 9001:2015, applicable sections of FDA 21CFR 820, and is registered with the FDA as a medical device manufacture. SWS-Trimac does not have any products, our clients maintain all design responsibility and highly committed to meeting our customer requirements.

We strive to be your path of least resistance. Often times, solutions do not always come easy. But, our perseverance in investigating alternative joint designs, fixturing, manufacturing techniques and materials, pays off!

Contact us and see how we can help.

© 2020 All rights reserved | SWS Trimac INC.