SWS-Trimac, Inc. has been providing Prototype Welding, Precision Machining, and Engineering Support to aid weld joint design, material selection, and process selection that best fits your application. No company can guarantee 100% success but with over 50 years of experience in Electron Beam Welding, Laser Welding, and Precision Machining we certainly have learned some lessons along the way and yield a very high level of success often after others have failed.

Electron Beam and Laser Welding has been an obvious choice for nearly every industry that seeks a high quality, low distortion solution to their welding challenges. Many clients have reaped the cost saving advantages of modular part manufacturing: less waste of raw material, and the reduction in machining time to manufacture. These advanced welding processes are used to join and array of alloys and dissimilar metal combinations.

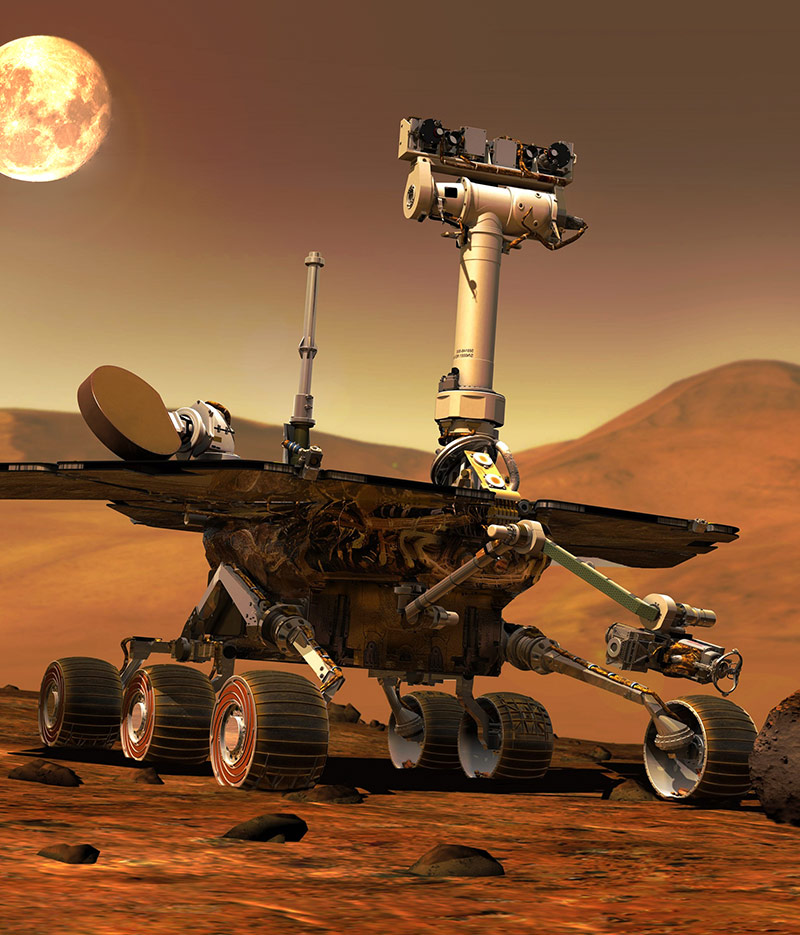

We have been asked to work on some extraordinary prototype projects over the years. Sometimes its parts for the space shuttle, Mars Rover, defense weaponry or automotive parts to set land speed records or even welding a meteorite can be thrilling. But working through the night, racing the clock, to tirelessly aid in the build of a prototype surgical implant to save a child’s life has been humbly our greatest honor!

Ford Motor Company had asked SWS-Trimac to assist in the build of the fuel cell used in the Fusion 999 vehicle. This was a major prototype Hydrogen Fuel Cell program for something that was never done before. This project entailed a tremendous amount of meticulous Prototype Welding using Electron Beam Welding supported through precision Machining, Wire EDM and Mass Spectrometer Leak Testing to assure leak tight weldments. SWS-Trimac takes no design credit, although we are very proud to have been selected to participate in Ford Motor’s record setting Fusion 999 vehicle that broke 207 miles per hour for a production style vehicle using Hydrogen.

Please take a moment to view the adjacent video as the large fuel cell shown was primarily fabricated within our facility, under customer direction to an extraordinarily tight timeline.

SWS-Trimac continues to support the military by providing Prototype Welding via Electron Beam and Laser Welding to aid in the manufacture of several weapons, missiles and countless tank and land based vehicle components. Additionally, SWS-Trimac supports many Aviation clients of which provide aircraft engines, landing gear hardware, hydraulics, instrumentation and helicopter transmission components. Electron Beam and Laser Welding are used daily to support the development of various Prototype Medical tools, instrumentation and surgical implants.

SWS-Trimac also supports countless Automotive clients whom manufacture combustion engines, transmissions, and various driveline parts for light, medium and heavy duty on and off road applications. Our diversity does not stop there; we supported various Green Technologies such as Wind, Solar, Lithium Battery, Bio Diesel, and Hydrogen Fuel Cell just to name a few.

We strive to be your path of least resistance. Often times, solutions do not always come easy. But, our perseverance in investigating alternative joint designs, fixturing, manufacturing techniques and materials, pays off!

Contact us and see how we can help.

© 2020 All rights reserved | SWS Trimac INC.